PC sheet bending process, how much do you really know?

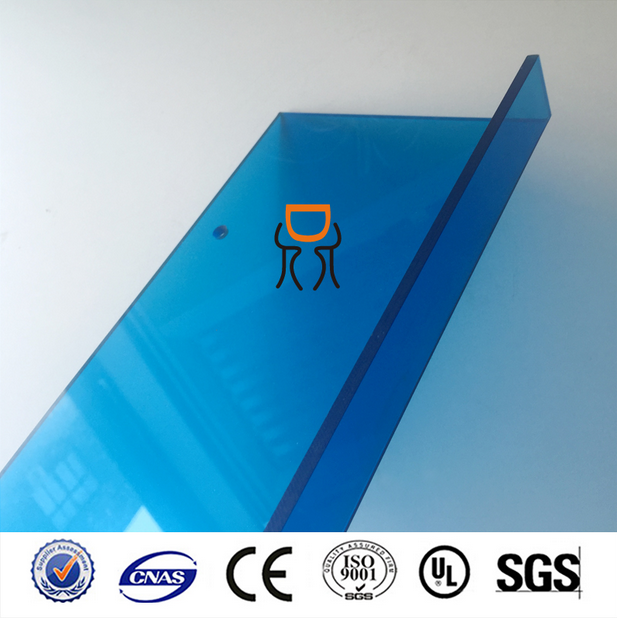

PC board bending, as the name implies, PC sheet in the bending machine die or die under the pressure of the first elastic deformation, and then enter the plastic deformation, in the beginning of plastic bending, PC sheet is free bending. With the pressure of the upper die or the lower die on the sheet metal, the inner surface of the V-shaped groove of the sheet metal and the lower die gradually close to each other. At the same time, the radius of curvature and the bending arm also gradually decrease. The pressure is continued until the stroke ends, so that the upper and lower dies and the sheet metal are in full contact with each other at three points. At this time, a V-shaped bending is completed, which is commonly known as bending.

Bending, a common PC board processing technology, is simple to operate. It has two functions, automatic and manual. In the automatic state, automatic function. After the board is put in, it will automatically bend and form within a preset time. The softening gap can be adjusted arbitrarily according to the thickness of the processed plate. The plate adopts fixed heating, so that the deformation after forming is smaller. Through the hand wheel angle setting, convenient and accurate, configuration by the rule to ensure the uniformity of batch products. The use of infrared heating method, than the furnace wire heating method greatly extended the service life. The voltage can be adjusted to avoid the phenomenon of pasting when folding thick plates from the surface. Configure the water circulation system, increase the cooling speed, and install the water temperature overheating alarm system to reduce the defective rate and ensure the safe use of the equipment. Leakage protection function, with grounding wire, to ensure the safety of construction and use.

Recommended News